Ganbaru Coffee

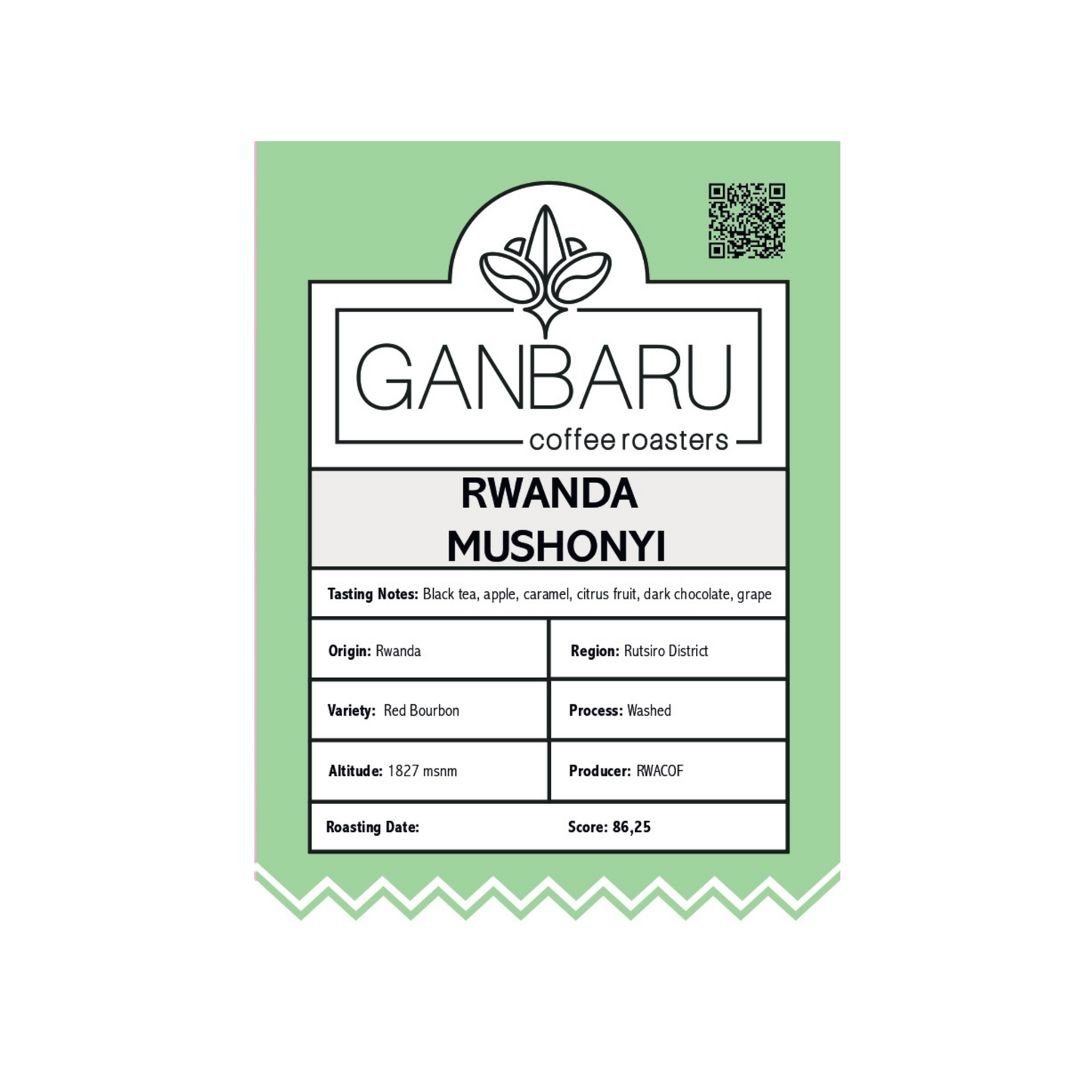

Rwanda Mushonyi

Rwanda Mushonyi

Couldn't load pickup availability

Country Producer: Rwanda

Region : Yirgacheffe

Tasting Notes : Black tea, apple, caramel, citrus fruit, dark chocolate, grape

Variety : Red Bourbon

Altitude : 1827 meters above sea level

Process : Washed

Producer : Rwacof

Washing Station: Mushonyi station

ABOUT THIS COFFEE

Mushonyi washing station is situated just one kilometer away from the shores of Lake Kivu. The 1,200 growers that deliver cherry to this station live and farm on the hills surrounding Mushonyi. In these hills, the altitude can vary from a low of 1,600 meters above sea level to a high of 1,950 meters above sea level. Farmers, on average, grow about 300 coffee trees on their small plots. Many also intercrop bananas, eucalyptus and cassava to generate additional income.

Mushonyi was originally built by the army. At the time, the army was anticipating high volumes of cherry, and they built to size. The station has eight fermentation tanks, a standard washing channel and cherry sorting shed for additional sorting before cherry is pulped. Rwacof maintains this infrastructure in pristine condition, even in years when the washing station's capacity exceeds the volume of cherry delivered.

HARVEST & POST HARVEST

After purchasing cherry from producers, Mushonyi sends the cherry through a strict sorting process. First, washing station staff remove any lower quality cherry through flotation. Then, a specially trained staff visually inspects the remaining cherry for any visual defects.

After the cherry is sorted, it is passed through a pulper. Mushonyi is equipped with a Pinhalense eco-pulper that can process up to 2 tons per hour. The machine integrates the flotation process and mechanical mucilage removal in its flow. From the hopper, the cherry flows into a basin. Here, the machine skims off the floaters and feeds them into a different channel for pulping. The good-quality cherry sinks and flows into a channel to be processed as high-quality.

Then, the coffee goes through a 10-hour fermentation in concrete tanks. Following fermentation, parchment is passed through a washing and grading channel. As the beans flow through, wooden bars that are laid across the canal prevent beans of specific densities from passing through. These bars are spaced across the channel. While the first blockade stops the most-dense beans, the next is arranged to stop the second most-dense beans and so on. In total, the process separates the patchment into five different grades.

Separated patchment is laid on raised beds to dry. Workers sort through drying patchment to remove any remaining defects that may have been obtained through the previous steps. Parchment is raked frequently to ensure even drying.

Compartir